Highly Reliable

No moving parts, optics or chemical reactions

Real Time & Accurate

10 sec measurement, accuracy <1.0% for pipeline gas specs

Ultra Compact

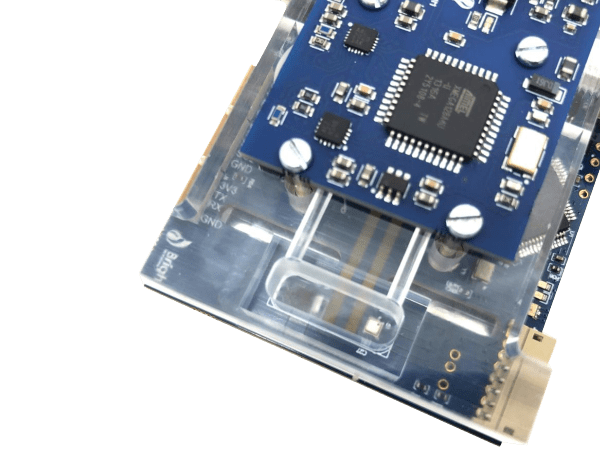

Sensor

dimensions BlueEye: 60 x 30 x 12 mm

Cost Effective

No OPEX. CAPEX: between 1/5th and 1/20th of an ordinary Chromatograph

Highly Reliable

No moving parts, optics or chemical reactions

Real Time & Accurate

10 sec measurement, accuracy <1.0% for pipeline gas specs

Ultra Compact

Sensor

dimensions BlueEye: 60 x 30 x 12 mm

Cost Effective

No OPEX. CAPEX: between 1/5th and 1/20th of an ordinary Chromatograph

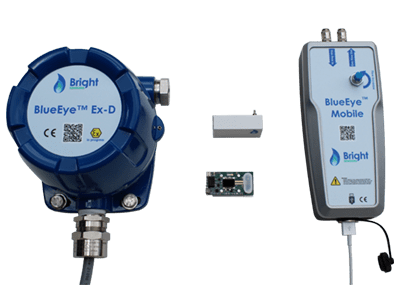

The main advantages of BlueEye™ sensors

Our unique and patented dynamic viscosity measurement principle combined with thermal conductivity measurement enables our sensors to achieve the highest possible accuracy for inference sensors at the lowest possible cost in absence of reoccurring cost.

The main advantages of BlueEye™ sensors

Our unique and patented dynamic viscosity measurement principle combined with thermal conductivity measurement enables our sensors to achieve the highest possible accuracy for inference sensors at the lowest possible cost due to the absence of reoccurring cost.

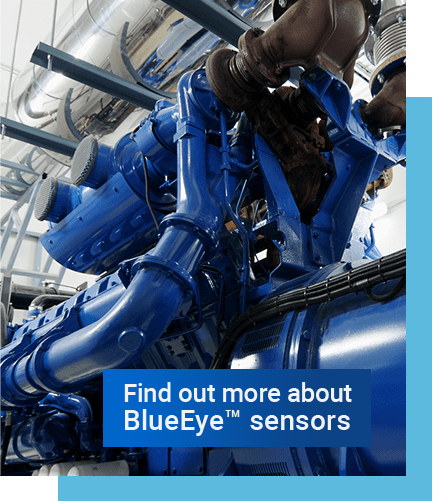

Where our analyzers are deployed

Industrial Gas Burners

Commissioning & tuning small boilers

Grid control management

Biogas & biomethane

Hydrogen

CNG & LNG Transportation

Fuel cells

Gas engines

OUR PARTNERS

The importance of Natural Gas – and its decarbonization

Natural gas is widely expected to overtake coal within the next 5 years and oil within the next 2 decades as the worlds largest primary fuel. When burned, natural gas releases up to 50% less CO2 than coal and 20-30% less than oil. Natural gas is easily storable, and therefore it is seen as a bridge fuel for renewables integration. Decarbonization of gas is taking place by Biomethane and Hydrogen blending into the natural gas. Unfortunately the gas quality is not constant and increasingly variable with more renewable gas injected into the grid on a more decentralized level. Bright Sensors` gas analyzers offer the perfect technical and economical solution to deal with this issue and therefore we enable decarbonization.

Contact info

Get in touch with us

Contact info